Online Service < 60s Email Reply Time < 24h

Processing Capacity: 10-500t/h

Processing Capacity: 10-500t/h

Output Size: 0.84-0.005 mm(20-2500 mesh)

Output Size: 0.84-0.005 mm(20-2500 mesh)

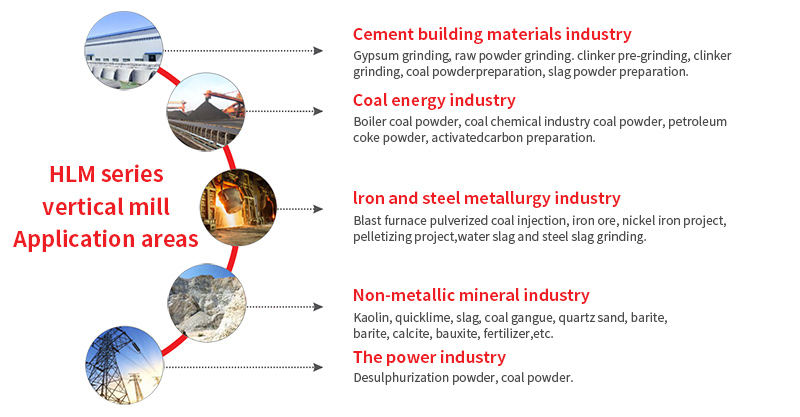

Applied Materials: Cement building materials industry, coal energy industry, iron and steel metallurgy industry, non-metallic mineral industry, the powder industry.

The VRM is a vertically placed large sized machine which is equipped with some rollers used for grinding raw material. It also consists of one table which is rotated by electrical motor & raw materials are feeded on the table. Due to centrifugal force on the table, raw material goes below the rollers (a gap between roller & table has to be maintain) automatically & start getting grinded. The rollers are driven by the friction between table & raw materials. The grinding process is done by exposing a bed of material to a pressure sufficiently high created by rollers which causes fracture on the individual particles in the bed. Due to such grinding, fine particles pass through the separator as the final product to the silo due to huge negative pressure in the mill & course particles falling down (separated by highly efficient separator)on the table for further grinding. Vertical Roller Mill can grind quartz, iron ore, river pebble, granite, basalt, diabase, limestone, calcite, dolomite, barite, talc, gypsum, bentonite, feldspar, fluorite, bauxite, slag, grain slag, clinker, granite, iron oxide yellow, barite, potassium, marble, lime, activated clay, activated carbon, bentonite, cement, phosphate rock, from 20 mesh into 2500 mesh.

Suitable grinding bed is easily obtained in vertical roller mill with high efficiency separator which ensures high fineness of product.

1. The sufficiently high enough to cause fracture of individual particles in the bed & most of the particles on the bed are considerable, smaller than the bed thickness.

2.A suitable grinding bed is easily obtained in vertical roller mill with high efficiency separator which ensures high fineness of product.

3.By automatic grinding process in the grinding bed, Uniform percentage of materials can be maintained which leads to perfect product compositionut size.

4. High fineness of material ensures more dense concrete with less possibility of chemical attack.

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM1300K | 10-40 | 200 |

| HLM1500K | 13-50 | 280 |

| HLM1700K | 18-70 | 400 |

| HLM1900K | 20-85 | 500 |

| HLM2200K | 35-135 | 800-900 |

| HLM2400K | 40-160 | 900-1120 |

| HLM2800K | 50-200 | 1120-1250 |

| HLM3400K | 70-260 | 1800-2000 |

| HLM3700K | 90-320 | 2500-2800 |

Note: The grindability (Bond) index of raw materials is less than or equal to 13kw/t

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM1200M | 6—10 | 110-132 |

| HLM1300M | 10-15 | 160—200 |

| HLM1500M | 15—20 | 220—280 |

| HLM1700M | 20-30 | 280-355 |

| HLM1900M | 26-35 | 355—450 |

| HLM2200M | 35-50 | 450—560 |

| HLM2400M | 45-55 | 560-710 |

| HLM2800M | 60-80 | 900—1120 |

Note:Raw coal HGl≥55

| Specifications | Feed particle size(mm) | Capacity(t/h) | Main motor power(kW) |

| HLM1200X | ≤10 | 2-6 | 132 |

| HLM1300X | ≤10 | 3-10 | 220 |

| HLM1500X | ≤10 | 4-13 | 315 |

| HLM1700X | ≤15 | 7-18 | 450 |

| HLM1900X | ≤15 | 8-23 | 560 |

| HLM2200X | ≤20 | 13-35 | 800 |

| HLM2400X | ≤20 | 15-45 | 1000 |

Note: Mohs hardness grade 4 or below

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM19S | 8-13 | 280-315 |

| HLM21S | 11-18 | 400-450 |

| HLM24S | 15-20 | 500-560 |

| HLM28S | 28-35 | 900-1000 |

| HLM35S | 70-80 | 1800-2000 |

| HLM42S | 95-110 | 2500-2800 |

| HLM46S | 130-150 | 3150-3800 |

| HLM53S | 160-200 | 4500-5000 |

Note: The grindability (Bond) index of raw materials is less than or equal to 18kw/t

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM17-2N | 6-10 | 200-220 |

| HLM19-2N | 8-13 | 280-315 |

| HLM21-2N | 10-15 | 400-450 |

| HLM24-2N | 12-18 | 500-560 |

| HLM28-2N | 22-30 | 900-1000 |

| HLM35-3N | 55-70 | 1800-2000 |

| HLM42-4N | 70-100 | 2500-2800 |

| HLM46-4N | 85-135 | 3150-3800 |

| HLM53-4N | 130-165 | 4500-5000 |

Note: Slag grindability (Bond) index ≤25kw/t; Steel slag grindability (Bond) index ≤30kw/t; The production of steel slag is reduced by about 30-40% when it is ground.