Online Service < 60s Email Reply Time < 24h

Processing capacity: 5-2200t/h

Processing capacity: 5-2200t/h

Feeding size: 125-1500mm

Feeding size: 125-1500mm

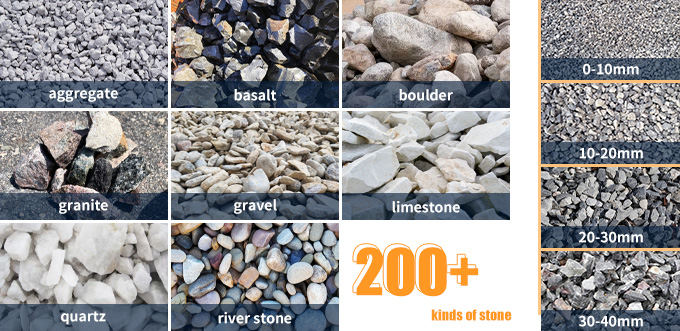

Applied material: limestone, iron ore, quartz, basalt calcite, all metal ores, dolomite, coal gangue, basalt, etc.

Stone crusher is one kind of stone crushing machine that can directly crush the material with 600-8000mm size to less than 25mm. It is widely used to crush all kinds of stones with soft, medium and high hardness such as gravel, rock, pebble, basalt, aggregate, barite, limestone fluorite, fledspar, dolomite, etc. It can be used for primary/secondary/fine crushing ofthe materials. Customized Output Size: 0-5mm, 5-10mm,10-30mm, 40-50mm, 1/2 inch, 3/4 inch, G1, G2, G3, sand and dust. etc.Application: road construction, sub-base, concrete work, brick and blocks, etc.

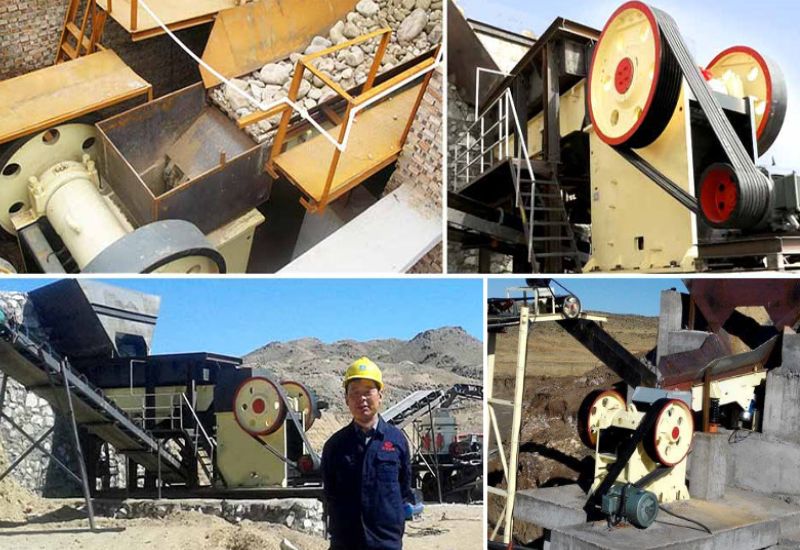

Unique Flywheel Design : Reduce vibration effectively, Machine work is stable.

Large Crushing Ratio : low suspension motion mechanism leads to greater crushing ratio.

Easy To Maintain : Application of high wear-resisting toothed plate, long maintenance period, and cost-saving.

We have various types of stone crusher machines, such as jaw crusher, cone crusher, impact crusher, hammer crusher, etc. Hot sale production capacity includes 10-30t/h, 30-50t/h, 60-80t/h, 80-120t/h, 150-200t/h, 200-300t/h, etc.

We provide you with different crushers and crushing plant solutions to save your costs according to your materials, sizes, output, and grades. We provide 100% factory price and maximum discount for you. Additionally, if you are new in this industry, we will provide professional suggestions and solutions for you.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.