Online Service < 60s Email Reply Time < 24h

Processing capacity: 1.9-76t/h

Processing capacity: 1.9-76t/h

Main motor: 7.5-160kw

Main motor: 7.5-160kw

Application area: slag industry, sandstone industry, building material, metallurgy industry, chemical industry, coal plants, pharmaceutical industry

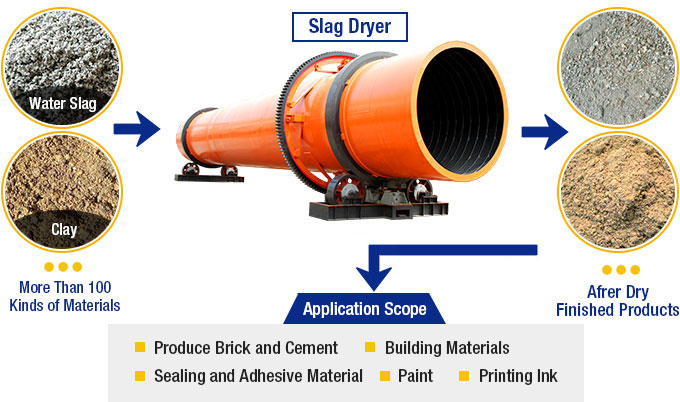

Slag dryer is a kind of drying machine used to dry steel slag, granulating slag, etc. With the simple structure and convenient application, slag dryer is a relatively affordable drying machine. Slag dryer is divided into different types according to its varying drying materials, such as the metal powder dryer used to dry metal powder and the iron concentrate dryer used for iron concentrate drying.

There are metal powder dryer, iron concentrate dryer, steel slag dryer and other series drying machines in Fote machinery. The drying machine in Fote Machinery has advantages of proper design, perfect craft, stable property, high production capacity, low energy consumption, small floor area, high degree of mechanization and strong extendibility. Slag dryer can not only dry steel slag, metal powder and iron concentrate, but also dry high humidity and large proportion materials such as limestone, clay, river sand, quartz and granulating slag.

Mixed with a certain amount of binding materials such as cement, the granulating slag is stirred, molded and steam cured, which is the process of producing bricks. Mainly used in cement production, granulating slag can serve as cement mixture, no clinker lime and the raw material of environmental protection cement brick.

As the replacement of kieselguhr, the drying slag can be used as heat-insulating filler to save investment costs.

The drying slag serves as sealing and adhesive material such as polyurethane, silicone, epoxy and so on.

The drying slag is used as water-based paint and oil paint.

The drying slag can serve as lithographic offset printing ink and plate printing ink, etc.

Technical parameters of indirect heat dryer:

(Dia.×Length)

(m³)

(t/h)

Shell

diameter

×shell

Length

ItemsInside

diameter

of outer

shell

(mm)Inside

diameter

of inner

shell

(mm)Shell

cubage

(m³)

Φ1.5×15m

1500

500

20.27

Φ1.5×17m

22.97

Φ1.5×19m

25.68

Φ1.8×21m

1800

650

35.91

Φ1.8×23m

39.33

Φ1.8×25m

42.75

Φ2.2×21m

2200

800

58.10

Φ2.2×23m

63.61

Φ2.2×25m

69.15