Online Service < 60s Email Reply Time < 24h

Processing capacity: 1-200t/h

Processing capacity: 1-200t/h

Main motor: 7.5-160kw

Main motor: 7.5-160kw

Applied material: river sand, quartz sand, sand, sand mining, ore, slag, blast furnace slag, fly ash, cinder, etc.

Sand dryer is suitable for high humidity and heavy property materials such as river sand, limestone, quartz sand and clay. The sand drying machine is applied to particle materials with a range of humidity such as yellow sand in construction industry, various specs sand in foundry industry, blast furnace slag in cement industry and granule materials with heat and smoke resistant and free chemical change in chemical industry.

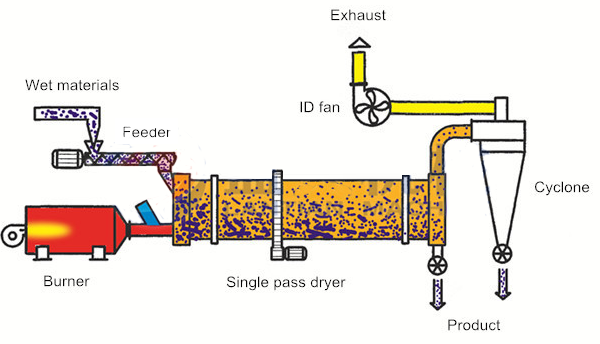

The sand is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The sand is added from the higher end, and the heating medium enters from the lower end, and is in countercurrent contact with the material. When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried, and then sent out through a belt or screw conveyor at the discharge end. In addition, dust collectors can also be used to reduce dust in the drying system.

1. The production capacity of the sand dryer is 1-200t/h; Fuel is suitable for hard coal, soft coal, gangue coal, oil and ash. The block material, grain material and powder material less than 20mm-40mm are all available;

2.There are about 50% reduction of civil engineering investment and 60% decrease on electric consumption;

3. With 65% primary moisture and less than 0.5%-1% final moisture, there is more than 59% heat efficiency improvement. About 60% floor area reductions make it convenient to install and save space;

4. Made of wear resistant manganese plate which is 3-4 times higher wear resistant than common plate, the river sand rotary dryer is durable.

6. With less than 60 degrees centigrade discharging temperature, the finished product can be sent into material warehouse without the cooling step;

6. With high technical content and self heat preservation effect, its heat efficiency is up to 80%. There are 68% coal savings and 100% production capacity improvement compared with the traditional sand dryer.

7. Outer barrel temperature and discharge temperature are all less than 60 degrees centigrade. However, the outer barrel temperature of the single-tube rotary dryer is up to 150 degrees centigrade.

Fote machinery is the sand rotary dryer best- selling manufacture and its sand rotary dryer is for sale at home and abroad. The affordable sand rotary dryer price is conducive to its popularity. Please no hesitate to join in us.

| Item/Unit/Model | Cylinder volume( m³ ) | Production capacity(T/h) |

| Φ2.5×7m | 16.63 | Yellow sand: 25-30 Slag: 20-25 |

| Φ2.7×7m | 16.63 | Yellow sand: 30-35 Slag: 25-30 |

| Φ3.0×7.0m | 52.678 | Yellow sand: 35-40 Slag: 30-35 |

| Φ3.2×7.0m | 52.678 | Yellow sand: 45-50 Slag: 35-40 |

| Φ3.6×8m | 81.38 | Yellow sand: 65-70 Slag: 60-65 |