Online Service < 60s Email Reply Time < 24h

Theoretical yield: 2-28t/h

Theoretical yield: 2-28t/h

Motor power: 5.5-75kw

Motor power: 5.5-75kw

Application area: coal and wear-resistant materials industries

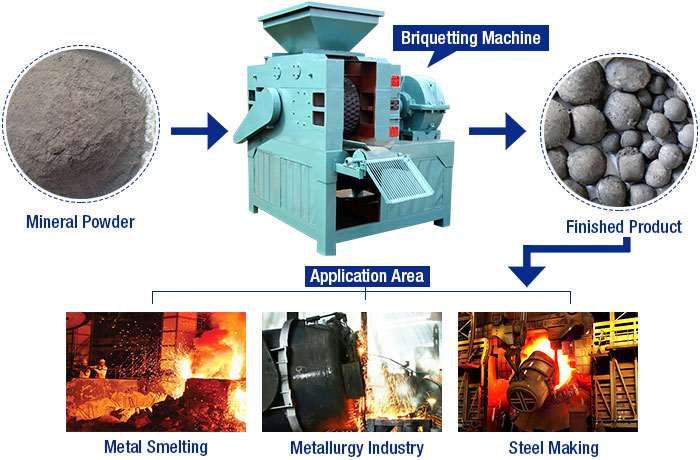

Fote mineral powder briquetting machine is proud of that the finished briquettes come with high intensity, great convenience for transportation and various shapes. Custom-made shape is also available. Additionally, the briquettes made by this nonferrous metal powder forming equipment can be used in blast furnace process and metal smelting as chemical and smelting auxiliary material. To be specific, the steel plants can supply mill scale briquettes made using this briquetting equipment to chemical plants for manufacturing ferrosilicon. Aluminum briquettes can be put into smelting furnace for extracting aluminum. Fluorite briquettes can be used as cosolvent for making steel.

Since that, this mineral powder briquette machine has found wide application in coal industry, metallurgy industry, chemical industry, etc. With this machine, mineral powder wastes can be recycled and compressed into useful and high-density briquettes which are small in size and convenient for transportation. Fote mineral powder briquetting machine has obtained great encouragement from the country and enterprises in that it can create considerable benefit for the enterprises while making mineral resources into full use.

1.Iron ore, manganese, chromium, nickel, iron concentrate fines, silicon manganese alloy, Iron scale, silicon carbide, manganese mineral powder, phosphorite ore, kaoline and other kinds of mineral powders.

2. Material should be less than 80-200mesh.

3. There shouldn't be any metallic material in the raw material to avoid damaging the surface of rollers.

4. Sufficient supply of raw material to make perfect and good-looking briquette.

Fote mineral powder briquetting machine is ideal mechanical equipment designed for processing mineral slag and powder generated during ore milling. Through being made into briquettes, these wasted mineral slag and powder can be reused in various industries, hence increasing additional value of mineral resources.

| Model | Roller Diameter (mm) |

Capacity (t/h) |

| FTMQ290 | 290 | 1-2.5 |

| FTMQ360 | 360 | 3-5 |

| Heavy FTMQ360 | 360 | 3-5 |

| FTMQ430 | 430 | 5-8 |

| Heavy FTMQ430 | 430 | 5-8 |

| FTMQ500 | 500 | 8-11 |

| FTMQ650 | 650 | 10-15 |

| FTMQ750 | 750 | 20-25 |

| FTMQ850 | 850 | 20-28 |

| FTMQ1000 | 1000 | 25-35 |