Online Service < 60s Email Reply Time < 24h

Processing capacity: 5–150m3/h

Processing capacity: 5–150m3/h

Feeding size: ≤350mm

Feeding size: ≤350mm

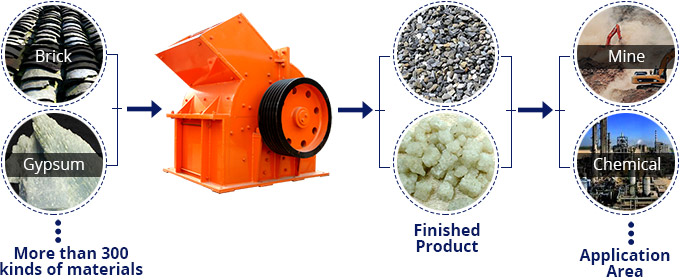

With the impact effect to crush materials, the hammer crusher is widely used in the mining, cement, coal, metallurgy, building material, highway and burning industries for crushing materials with the medium hardness and brittle property. The grate gap of hammer crusher can be adjusted according to different particle size requirements of users. Hammer crushing machine can be divided into 2 types: heavy hammer crusher and ring hammer crusher.

1. Advanced design craft, high constitutive property and strong impact resistance;

2. Large amount of feeding size, high finished product ratio and pretty particle shape;

3. Super crushing ability, one step to coarse, secondary and fine crushing;

4. 30% increase of the production capacity, 20% reduction of needle-like and powdery products;

5. Chromium manganese alloy material of the hammer and sieve plate, stronger impact resistance and abrasive resistance;

6. Adjustment of the particle size according to the varying customers' needs.

The hammer crusher is suitable for materials with the medium hardness and less abrasiveness, whose compressive strength is less than 100 MPa and moisture content is no more than 15%, such as chalk, coal, salt, gypsum, bricks and limestone. With the advanced property and steady reliability, the hammer crushing machine is widely used in the cement, sand, coal, building materials, chemical, power, metallurgy, highway construction, and compound fertilizer industries for fine crushing of the medium hardness materials in the refractory plant, cement plant and glass plant. Besides its use in the crushing production line and sand making production line, to be the replacement of the cone crusher, the hammer mill crusher is also available for the beneficiation production line.

If you want to know our hammer mill crusher price, please send email to info@sinoftm.com or contact our online customer services.

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.