Online Service < 60s Email Reply Time < 24h

Specification: φ1.83×7~φ4.6×14m

Specification: φ1.83×7~φ4.6×14m

Processing Ability: 6.5-135t/h

Processing Ability: 6.5-135t/h

Applied Materials: Cement, silicate products, new building materials, refractory materials, chemical fertilizer, etc.

Application Fields: Black and non-ferrous metals industry, glass ceramics industries and other production sectors.

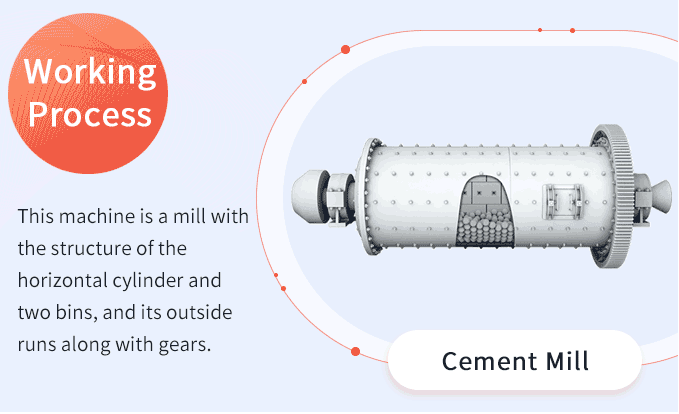

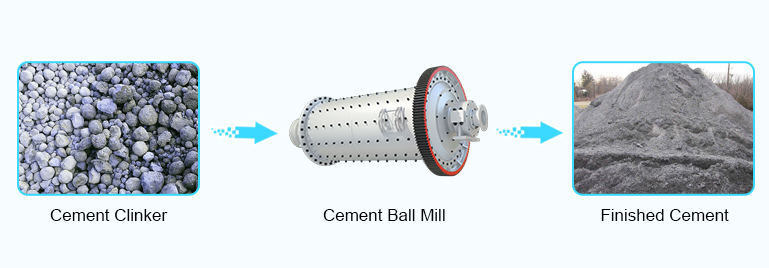

Cement mill is the key equipment for smashing materials after coarse crushing, which is suitable for dry or wet grinding of various ores and other materials. It is widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and non-ferrous metals, glass ceramics and other sectors. Sometimes, people also call cement mill as cement grinding mill, cement grinding machine and cement grinder.

1. High grinding efficiency. The material bed pressure crushing principle is adopted for the rolling, shearing and impacting of materials in the mill. The airflow inside the mill can bring out the ground materials to avoid over-grinding.

2. Large feed granularity. It usually takes up 5% diameter of the grinding roller. Cement mill has superior performance, large output and high operation rate.

3. Strong adaptability to various materials. It can be used for grinding various raw materials such as limestone, sandstone, coal, cement clinker, hopper, blast furnace slag etc.

4. Excellent overall airtight, less dust, low noise and superior working conditions.

5. The fast quality control and flexible adjustment of products make it easy to realize intelligent and automatic operations.

Fote Machinery is a professional cement mill manufacturer, whose products are exported more than 130 countries. The cement mill produced by Fote is in accordance with international production standards, which has quality assurance and after-sales services. Welcome to contact us to get cement mill price.

| Product specification (m) |

Milling form | Production capacity (t/h) |

| Φ1.83×7 | Open flow | 6.5-8 |

| Φ2.2×7.5 | Open flow | 8-10 |

| Φ2.2×11 | Open flow | 12-13 |

| Φ2.2×13 | Open flow | 16-18 |

| Φ2.4×13 | Open flow | 20-23 |

| Φ2.6×13 | Open flow | 28-32 |

| Φ3×9 | Circle flow | 28-36.5 |

| Φ3×11 | Circle flow | 36-47 |

| Φ3.2×13 | Open flow | 45-50 |

| Φ3.5×13 | Circle flow | 60-65 |

| Φ3.8×13 | Open flow | 60-62 |

| Φ4.2×13 | Open flow | 85-87 |

| Φ4.6×14 | Circle flow | 120-135 |