Online Service Connection < 60s Email Reply Time < 24h

Bentonite whose main component is montmorillonite is a natural nonmetallic material. With perfect physical and chemical property, bentonite serves as binder, suspending agent, thixotropic agent, stabilizer, purification decolorant, filling material, fodder and catalyzer.

Bentonite whose main component is montmorillonite is a natural nonmetallic material. With perfect physical and chemical property, bentonite serves as binder, suspending agent, thixotropic agent, stabilizer, purification decolorant, filling material, fodder and catalyzer.

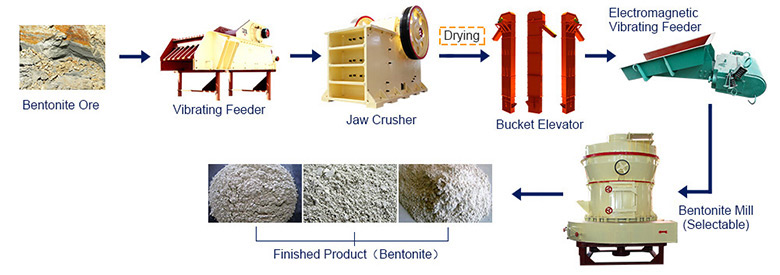

The bentonite is widely used in the agricultural, light industry, cosmetic and medical fields. However, without the direct usage of the bentonite, bentonite can be used after its powdery processing with grinding equipment.

Bentonite clay grinding is a kind of grinding equipment aiming at the physical and chemical property of bentonite. The common bentonite finenesses are 300 meshes, 325 meshes, 400 meshes, 500meshes, 600 meshes, 800 meshes, 1000 meshes, 1250 meshes and so on. With the bentonite super fine grinding mill, fine powder with any fineness is available. With the discretionary adjusted fineness, its general processing fineness is between 325 meshes and 1250 meshes.

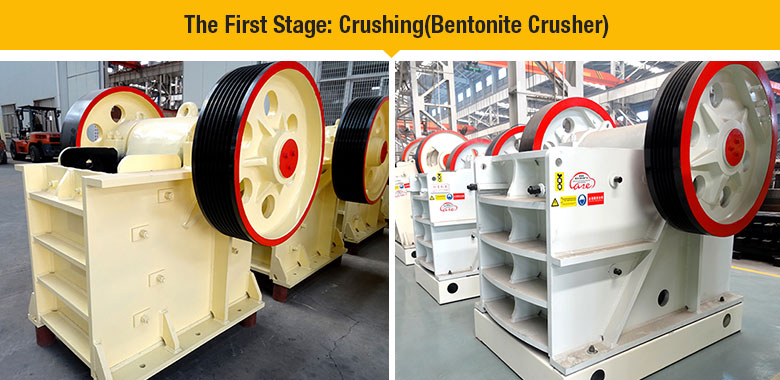

With the 1-2 Mohs hardness, bentonite belongs to non-metallic mine with a soft character. According to its property, we can make a primary crushing with bentonite crusher.

Natural moisture removal and heat drying moisture removal are all available. Less than 250℃ drying temperature and not too long drying time is necessary in case of the bentonite property transform caused by montmorillonite structure change.

To satisfy the high fineness needs of bentonite in paper making, plastic and rubber products fields, we need choose raymond grinding mill to make super fine grinding and micro grinding.

Package the finished products and send them to the market.