Online Service < 60s Email Reply Time < 24h

Processing capacity: 0.65-615t/h

Processing capacity: 0.65-615t/h

Feeding size: ≤25mm

Feeding size: ≤25mm

Applied material: cement, silicate, new-type building material, refractory material, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc.

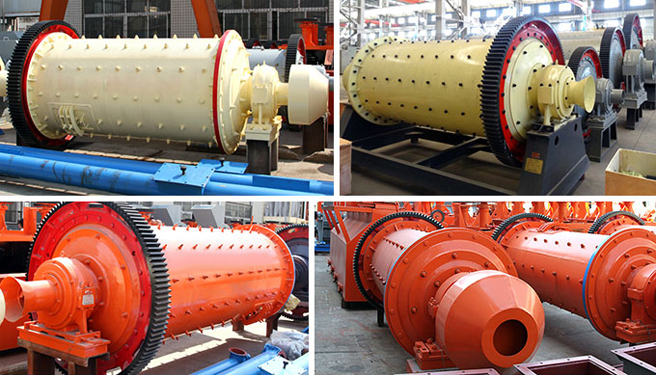

Ball mill is used for the grinding work of the crushed ore. According to the different materials and discharging methods, there are grate-type ball mill and overflow ball mill for choice. Wet-type and dry-type grinding are all available. The ball grinding machine is widely used in the ore beneficiation plant, ceramics, cement plant, coal mining, gold mining mineral grinding, construction waste, cement clinker and metal. Ball Mill can be used for grinding gold ore, iron ore, copper, nickel ore, chrome, lead, zinc, tin, limestone, mica, feldspar, quartz, silica sand, gypsum, slag, cement, clinker, coal, barite, hematite ore, graphite, sand, mineral ores, etc.

According to the varying process materials, grinding ball mill in Fote machinery can be divided into the following types: gold ore ball mill, quartz ball mill, iron copper minerals ball mill, tin ore ball mill, limestone ball mill, garnet ball mill, cement ball mill, fluorite ball mill, feldspar ball mill, etc.

Made of super wear-resistant material in its bearing, steel ball and wheel gear, there is more than 3 times improvement on abrasive resistance of the grinding ball mill. With the effective improvement on pressure resistance, corrosion resistance and abrasion resistance of components, the ball mill has a considerably reliable quality and a 5-year longer using life.

With the perfect grain shape, uniform particle size and high quality grinding materials, the ball mill can satisfy the ideal material needs in different industry fields.

With the relatively large diameter design of the feeding port and the discharge hole, the handling capacity per unit is 3-5 times larger than the same type ball mills in the market.

More reasonable double-check of technical parameters improve the grinding efficiency by more than 40%. Grinding ball mill in Fote machinery is the most effective ore grinding equipment in the current market.

The unique sliding bearing design effectively reduces the friction rates of different structure, the repair costs and the energy consumption unit time.

Equipped with advanced dust-proof insulation device and sealing device, the ball mill is totally qualified with the national environment protection standards and has an obvious environmental protection effect.

As one of the reliable ball mill manufacturer in China, we has different kinds of ball grinding machine for sale. Unsurpassable advantages in ball mill price, quality and property help it to be the most ideal choice of the grinding equipment. Sincerely welcome old and new users visit and purchase from our company, at that time we will provide you the high-class ball mill machine and perfect after-sale service. You are welcomed to leave your message on our website directly or consult our online service for ball mill price.

| Model | Feeding size (mm) |

Capacity (t/h) |

| Ф900×1800 | <20 | 0.65-2 |

| Ф900×3000 | <20 | 1.1-3.5 |

| Ф1200×2400 | <25 | 1.5-4.8 |

| Ф1200×3000 | <25 | 1.6-5 |

| Ф1200×4500 | <25 | 1.6-5.8 |

| Ф1500×3000 | <25 | 2-5 |

| Ф1500×4500 | <25 | 3-6 |

| Ф1500×5700 | <25 | 3.5-6 |

| Ф1830×3000 | <25 | 4-10 |

| Ф1830×4500 | <25 | 4.5-12 |

| Ф1830×6400 | <25 | 6.5-15 |

| Ф1830×7000 | <25 | 7.5-17 |

| Ф2100×3000 | <25 | 6.5-36 |

| Ф2100×4500 | <25 | 8-43 |

| Ф2100×7000 | <25 | 12-48 |

| Ф2200×4500 | <25 | 9-45 |

| Ф2200×6500 | <25 | 14-26 |

| Ф2200×7000 | <25 | 15-28 |

| Ф2200×7500 | <25 | 15-30 |

| Ф2400×3000 | <25 | 7-50 |

| Ф2400×4500 | <25 | 8.5-60 |

| Ф2700×4000 | <25 | 22-80 |

| Ф2700×4500 | <25 | 26-90 |

| Ф3200×4500 | <25 | As per process conditions |

| Ф3600×4500 | <25 | As per process conditions |

| Ф3600×6000 | <25 | As per process conditions |

| Ф3600×8500 | <25 | 45.8-256 |

| Ф4000×5000 | <25 | 45-208 |

| Ф4000×6000 | <25 | 65-248 |

| Ф4000×6700 | <25 | 75-252 |

| Ф4500×6400 | <25 | 84-306 |

| Ф5030×6400 | <25 | 98-386 |

| Ф5030×8300 | <25 | 118-500 |

| Ф5500×8500 | <25 | 148-615 |